Winston Manufacturing is Winston Industries’ contract manufacturing division. We’re an American company headquartered in Louisville, Kentucky.

We are constantly investing in state-of-the-art equipment to manufacture projects accurately and economically. We offer services that smaller fabricators cannot handle. Our team is cross-trained, so they understand production capabilities and requirements. This means superb collaboration, higher quality, better delivery times, and cost savings. Contact us today for a quote on your manufacturing project.

Our Services

Contract Manufacturing

Punching

Laser Cutting

Forming

Laser Welding

Grinding and Finishing

Machining

Metal Bending

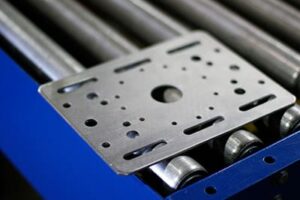

Winston Manufacturing offers you superior metal bending capabilities. Our state-of-the-art equipment and decades of metalworking expertise enable us to take on any project.

Metal Fabrication

Winston Manufacturing offers you superior metal bending capabilities. Our state-of-the-art equipment and decades of metalworking expertise enable us to take on any project.

- Metal Cutting

- Metal Bending

- Salvagnini Panel Bender and Press Brakes

- Certified Welding

- Assembly

Certified Welding (ANSI/AWS Certifications in aluminum, stainless steel, and mild steel)

- Continuous seam welding

- Spot welding

- Stud welding

- Certified TIG welding

Assembly

- Full assembly and test capability

- Electronics and computerized control assembly

Our Equipment

Investing in Technology

- Salvagnini SL4 Punch/Laser Combination

- Salvagnini P4 Panel Bender with Cut Option

- Virtek Laser Inspection

- Accurpress Press Brakes

Contact Us

Winston Manufacturing is a U.S. based company headquartered in Louisville, Kentucky. We are located within a day’s drive of 65% of the American population.